Quality Management

WE, AS POLAT MAKINA A.Ş., WHO CARRIES OUT THE DESIGN, MANUFACTURING AND SERVICE ACTIVITIES OF CONTINUOUS SYSTEM OLIVE OIL EXTRACTION MACHINES AND DECANTERS, SEPARATORS AND AUXILIARY EQUIPMENT USED IN VARIOUS INDUSTRIAL APPLICATIONS;

COMMIT AND DECLARE AS AN INTEGRATED MANAGEMENT SYSTEM POLICY THAT;

- WITH OUR INTEGRATED MANAGEMENT SYSTEM THAT WE HAVE CREATED IN LINE WITH OUR VISION, MISSION, PRINCIPLES, GOALS AND CORPORATE VALUES, we CARRY OUT ALL OUR PRODUCTS, SERVICES AND ACTIVITIES IN ACCORDANCE WITH QUALITY, ENVIRONMENT, OCCUPATIONAL HEALTH AND SAFETY, TO VALID FOOD SAFETY MANAGEMENT SYSTEMS WITHIN THE FRAMEWORK OF APPLICABLE NATIONAL AND INTERNATIONAL STANDARDS, LEGAL REGULATIONS AND OTHER REQUIREMENTS,

- TO ENSURE AND INCREASE THE SATISFACTION OF ALL RELEVANT PARTIES IN THE BEST MANNER WITHIN THE FRAMEWORK OF CORPORATE MANAGEMENT PRINCIPLES BY RECEIVING AND REGULARLY MEASURING THE OPINIONS, REQUESTS AND EXPECTATIONS OF OUR STAKEHOLDERS, INCLUDING CUSTOMERS, EMPLOYEES AND SUPPLIERS,

- TO IDENTIFY AND SUPPLY THE SKILLED MANPOWER, KNOWLEDGE, INFRASTRUCTURE AND ENVIRONMENT REQUIRED FOR THE EFFECTIVE OPERATION, CONTROL, SUSTAINABILITY AND CONTINUOUS IMPROVEMENT OF PROCESSES WITH PROCESS-BASED, PREVENTIVE APPROACH AND RISK-BASED THINKING,

- WITH THE PARTICIPATION OF OUR RELEVANT STAKEHOLDERS AND TAKING INTO ACCOUNT THE BEST PRACTICES IN THE SECTOR AND IN THE WORLD, TO SET MEASURABLE TARGETS FOR QUALITY, ENVIRONMENT, OCCUPATIONAL HEALTH AND SAFETY, FOOD SAFETY MANAGEMENT SYSTEMS, REGULARLY REVIEW THE REALISATION AND CONTINUOUSLY IMPROVE OUR PERFORMANCE AND OUR PRODUCTS, SERVICES AND MANAGEMENT SYSTEMS,

- TO GIVE VALUE TO ALL OUR EMPLOYEES, CONTINUOUSLY TRAIN THEM IN ORDER TO IMPROVE THEIR AWARENESS OF QUALITY, FOOD SAFETY, ENVIRONMENT AND OCCUPATIONAL HEALTH AND SAFETY, AND TO WORK WITH A TEAM SPIRIT IN LINE WITH THE GOALS AND POLICIES OF OUR ORGANISATION WITH THE PARTICIPATION OF ALL OUR EMPLOYEES,

- TO PROVIDE ALL THE QUALITY AND HYGIENE CONDITIONS NECESSARY TO PROTECT THE HEALTH OF OUR CUSTOMERS, TO OBEY ALL THE NECESSARY RULES FOR OUR CRITICAL CONTROL POINTS AND THEREFORE TO PROVIDE PRODUCTS AND SERVICES IN A SAFE ENVIRONMENT,

- TO COMPLY WITH ENVIRONMENTAL LEGISLATION, ADMINISTRATIVE REGULATIONS AND SECTORAL OBLIGATIONS,

- TO PREVENT POLLUTION AT THE SOURCE BY TAKING INTO ACCOUNT THE ENVIRONMENTAL TOLL OF ALL OUR ACTIVITIES, TO TAKE MEASURES TO REDUCE OUR WASTE AND THE USE OF NATURAL RESOURCES, TO INCREASE THE RECYCLING RATE, TO DEVELOP AND ENCOURAGE OUR RECYCLING METHODS,

- TO CHOOSE ECO-FRIENDLY AND ENERGY EFFICIENT PRODUCTS AND SERVICES

- TO COMPLY WITH OCCUPATIONAL HEALTH AND SAFETY LEGISLATION AND ADMINISTRATIVE REGULATIONS; TO CREATE A HEALTHY, SAFE AND ERGONOMIC WORKING ENVIRONMENT.

- BY PRINCIPLE OF ZERO ACCIDENT AND ALL KINDS OF OCCUPATIONAL ACCIDENTS AND OCCUPATIONAL DISEASES ARE PREVENTABLE, ELIMINATING ALL RISKS THAT MAY DISRUPT THE HEALTH INTEGRITY OF OUR EMPLOYEES AND ALL RELATED PARTIES BY TAKING THE NECESSARY MEASURES BY IDENTIFYING WITH A SYSTEMATIC AND PREVENTIVE APPROACH WITH ENSURING THE HIGHEST LEVEL OF PARTICIPATION OF OUR EMPLOYEES AND TO MAKE IT SUSTAINABLE.

- TO BE A PIONEER AND INNOVATIVE COMPANY,

- TO BE A MANUFACTURER THAT ACHIEVES FAULTLESSNESS IN ALL THE PRODUCTS AND SERVICES WE OFFER AND IN EVERY WORK WE DO,

- TO HAVE A GOAL BEING A LEADER IN THE SECTOR IN THAT WE OPERATE BY INCREASING OUR COMPETITIVENESS AND PROFITABILITY,

- THAT OUR POLICY IS ALWAYS OPEN PUBLIC AND ACCESSIBLE TO THE COMMUNITY AND ALL INTERESTED PARTIES,

Quality Control Process

Quality control activities are realized in an effective way in all processes including the process stages from supply process of input products to the shipment of machinery manufactured.

Input Quality Control

Input Quality Control: Spectral Composition Analysis

Input Quality Control: Spectral Composition Analysis

Input products supplied from our national and international suppliers under the purchase specifications of Polat Makina are controlled in full by the input quality control department.

Input products are controlled based on the measures, materials, endurance, color, visual and other characteristics and requirements specified in the technical images, product specifications or product technical certifications.

Control activities whether the input products comply with the measures and geometrics specified in the technical images and specifications are realized through measuring tools such as caliper, micrometer, CMM measure device, etc.

Products such as stainless steel, peak, sphero, etc. in different alloy and material characteristics produced through different processes such as forging, casting, etc. are supplied with supplier reports and certifications including the material heat treatment and measurement report.

In the input product controls, chemical compositions of the material is measured through spectrometer and mechanical and heat treatment characteristics are measured through hardness testing machine. The product is controlled whether it is in the range specified in the specification and it is compared to the supplier reports.

Input approval procedure of each input product batch is reported in details and recorded. Batches and products which are considered suitable as result of the assessment are approved over SAP and placed on the raw material storage. Traceability is ensured by 100% based on batch number and supplier.

Polat Makina A.Ş controls and assesses the quality performances of its suppliers constantly and develops it by feedbacks. It takes actions to increase the quality performances of its suppliers with constant improvement methodology and secures the input product quality in a sustainable way through the supplier visits and inspections.

Process Quality Control

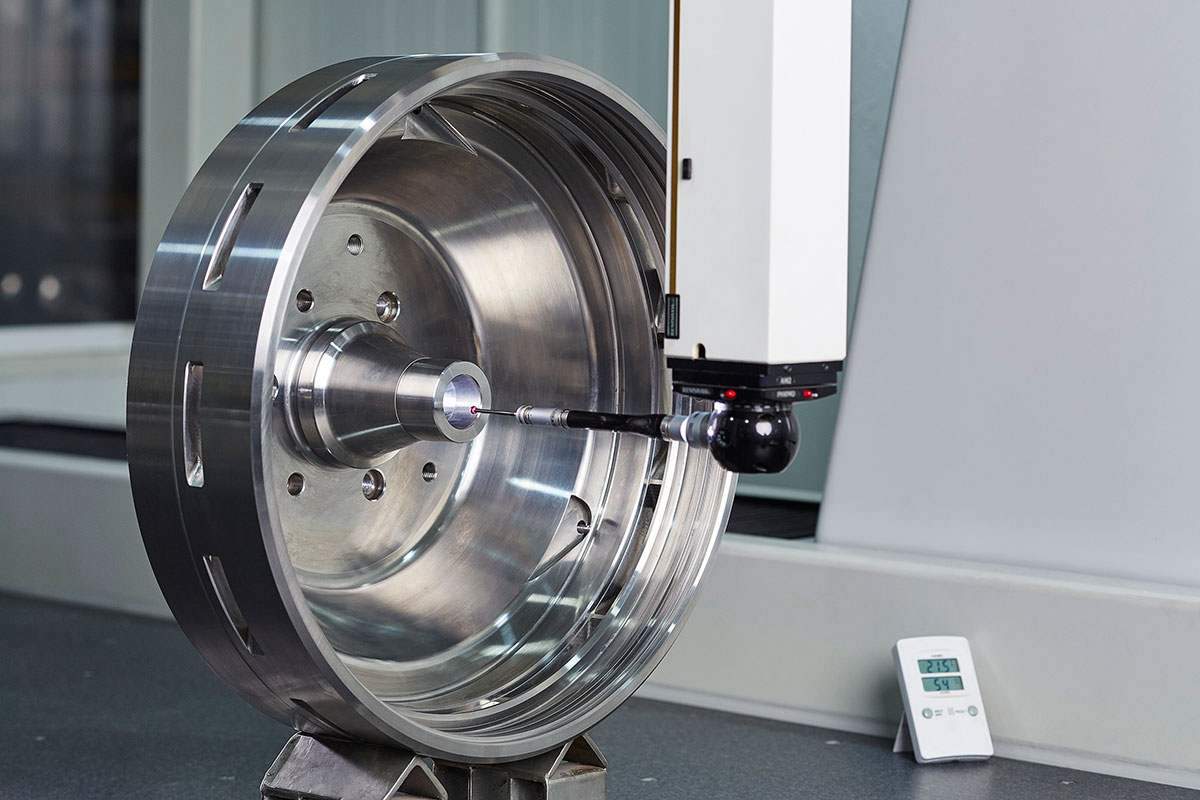

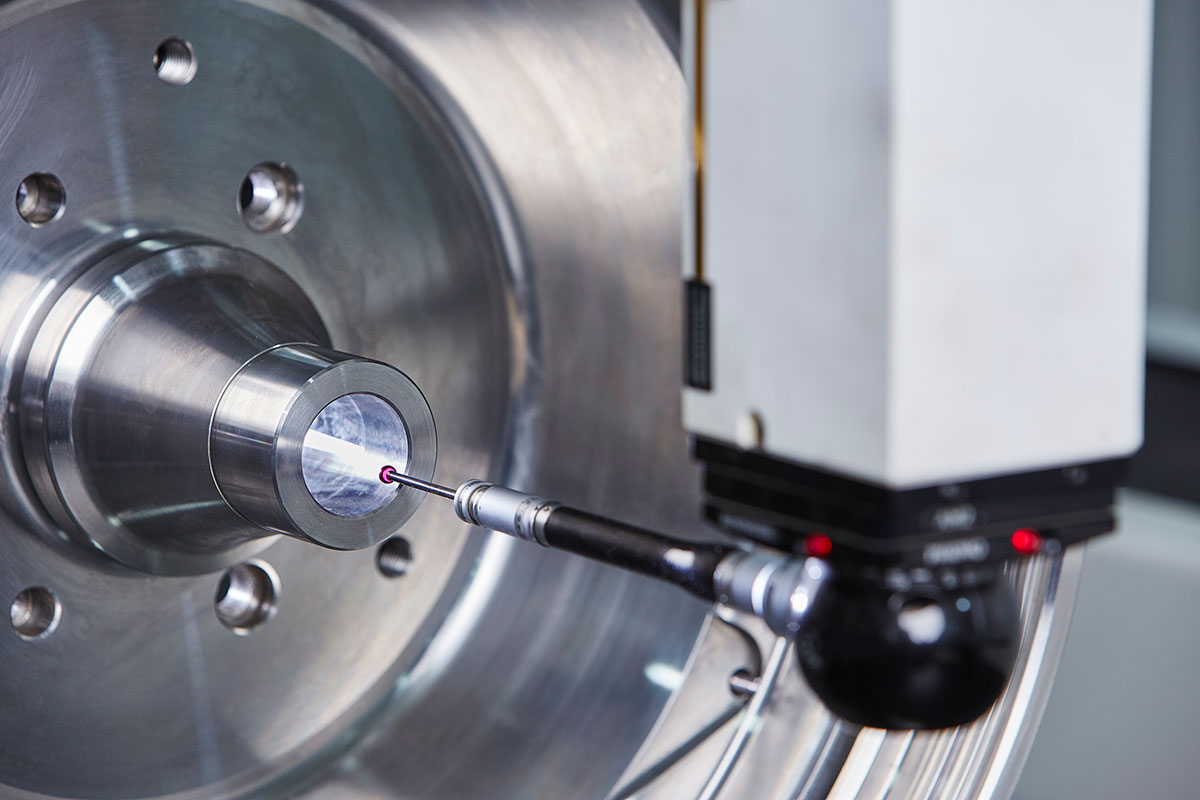

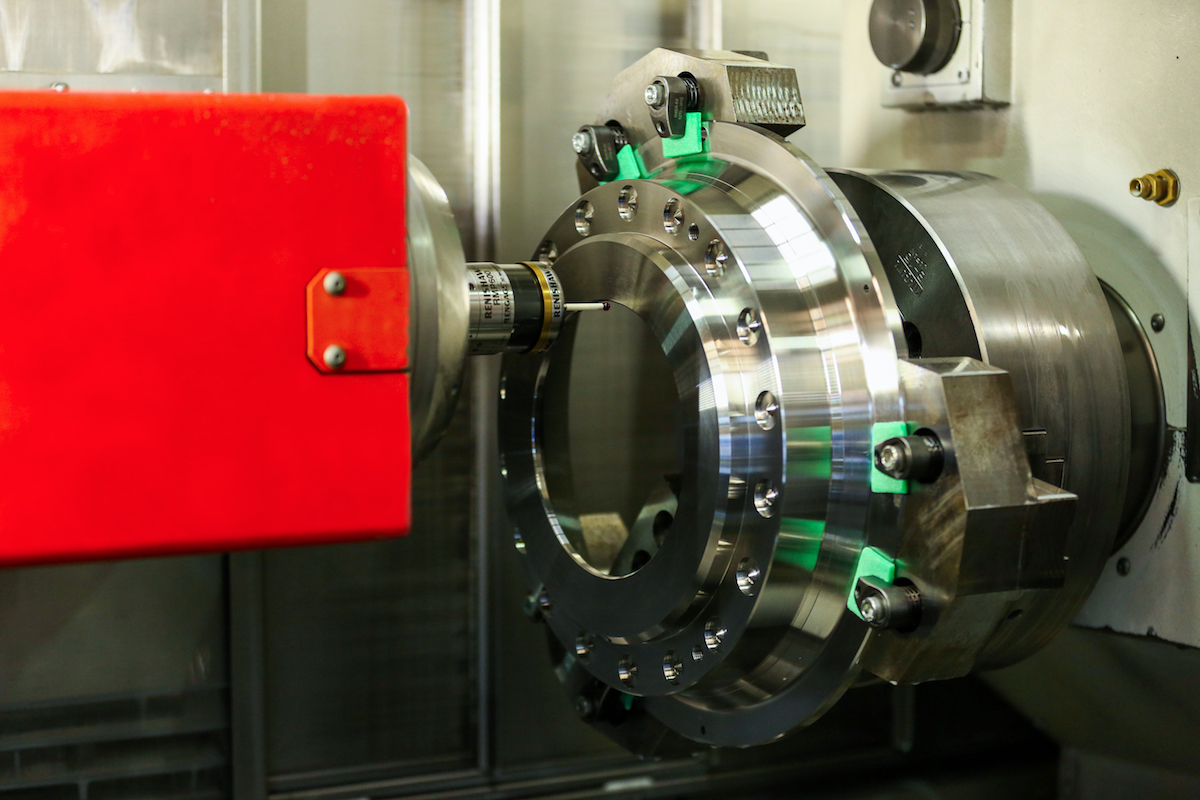

Process Quality Control: CMM Measuring and Scanning at Bench

Process Quality Control: CMM Measuring and Scanning at Bench

They are the quality control operations applied in the material preparing, machining, metal works, assembly and painting processes.

Whether the first part manufactured after the installation at the related process and bench complies with the measurements and requirements specified in the technical image is controlled by the quality team. If the part is measured, scanned and controlled, the quality department gives the first approval to the production department for the part. The production begins based on the first approval mechanism.

All main and sub processes such as cutting, bending, perforating, turning, milling, hatching, grinding, trimming, welding, detensioning, pickling-washing, sanding, painting, installation are controlled effectively.

While the production is ongoing, quality department realizes sampling as frequency and the production department controls and reports all parts manufactured.

The quality of parts manufactured in the process are assured and the parts which are not suitable for the new stage are prevented.

The results of measurements on parts and processes are observed statistically by SPC methodology. Performances and competencies of bench and process are tracked constantly.

Measurements and controls are realized through equipment of which calibrations are suitable for the process. Calibration process of testing and measuring tools used in the firm are tracked effectively and calibration activities are realized periodically by the accredited institutions.

Final Quality Control

Final Quality Control: Vibration Test

Final Quality Control: Vibration Test

During the detailed final quality control process realized before the shipment, continues systems, decanters, separators, malaxators, breakers, washing machines, conveyor belts, feed screws, seed separators, vibrations, pumps, boilers and boards are controlled based on product technical image and specifications.

Following visual and functional controls are realized meticulously based on the product type and working principle.

Results of the controls and measurements are written on the final quality control approval form with the serial number of the machinery and reported and stored. Therefore, traceability is provided for each machinery.

As the result of the controls realized, machinery which meets all requirements are sent to the shipment department as ready for the shipment after being attached with the quality control approval label by the quality department.

Controls realized in the final quality control process:

- Detailed installation controls,

- Working test,

- Water leakage test,

- Noise (sound level) test,

- Engine vibration control,

- Chassis/body vibration control,

- Body cycle controls,

- Screw cycle controls,

- Body and screw engine current,

- Shaft cycle controls,

- Bed vibration control,

- Bed temperature controls,

- Input product debit,

- Transmission control,

- Tore control,

- Board electricity test,

- Paint thickness measurement,

- Surface fault and stainless control on stainless surfaces,

- Surface fault and color control on painted surfaces,

- Cleaning control of welded surfaces,

- On-machinery label controls,

- Package controls.

Perfection of our products are controlled with 3D coordination measurement devices.

Infrastructure of testing and measuring tools of Quality Control Department

- CMM Measuring Device

- Surface Roughness Measuring Device

- Ultrasonic Thickness Measuring Device

- Hardness Measuring Device

- XRF Spectral Analysis Device

- Vibration Measuring Device

- Audio-level meter

- Shore-meter

- Surface Thermometer

- Calipers

- Micrometers

- Cylinder Comparator

- Spring Gauges

- Mitre

- Radius Gauge Set

- Buffer, Ring, Screw, Gauge Sets

- CE Testing Device

- Calibration Kits

As a result of our company's sensitivity to quality systems, we have earned the following quality certifications: