Olive Oil Process Units

Polat Makina manufactures compact and modular process equipment which your process is in need of and use innovate technologies and control all processing stages automatically.

All equipment needed in the system are produced by Polat Makina in compliance with food regulations and CE standards. In addition to the turnkey units for our customers, we provide economical solutions with single machinery options which you will need in your production process.

Olive Oil Process Units Advantages:

- Product portfolio in suitable capacities for your needs,

- Easy adaptation for other processes,

- Modular designs in capacity increases,

- Customized production and R&D researches,

- Full protection against abrasion,

- Designs in compliance with food, occupational health and safety,

- Low energy consumption,

- Easy to use, low labor cost,

- Less area requirement,

- Low carbon emission,

- Low maintenance cost,

- Fast and solution oriented service,

Process Units

It is the equipment which enables your product to be carried to the next equipment in a problem-free and constant way. It has a conveyor belt suitable for chassis manufactured from stainless material, driving system of which speed can be adjusted and in compliance with CE standards and food regulations. We have alternatives in different sizes and capacities based on your needs.

It is the equipment which enables your product to be clean off dust, stone and sand and provides a cleaner product output in a cleaner condition constantly. Whole device is manufactured from stainless steel. It complies with food regulations and CE standards. When adapted to your system, the quality of your product increases as the result of the cleaning off the unwelcome materials. We have models including “leaf aspirator” and “Blower”. We provide customized solutions in order to realize production in each capacity.

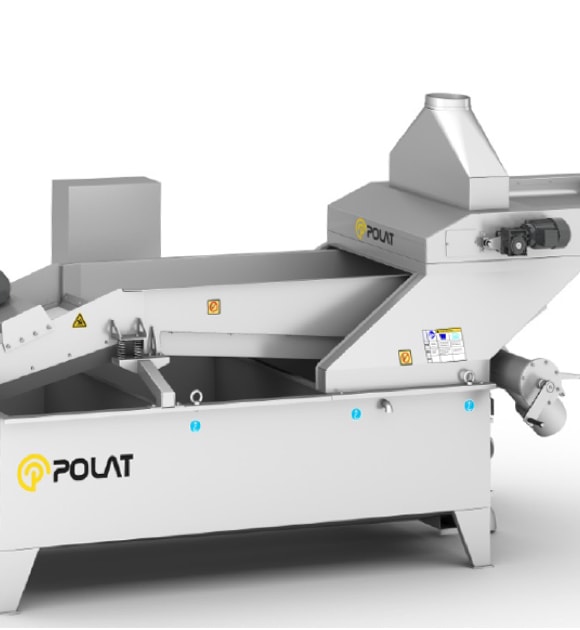

Minimizing the products cleaned and washed into a particular size is an important process to obtain the oil from the inside. Our olive breakers in high capacities and different models are designed to meet all needs of your business facility. All of our products are manufactured from stainless steel in compliance with food regulations and CE standards.

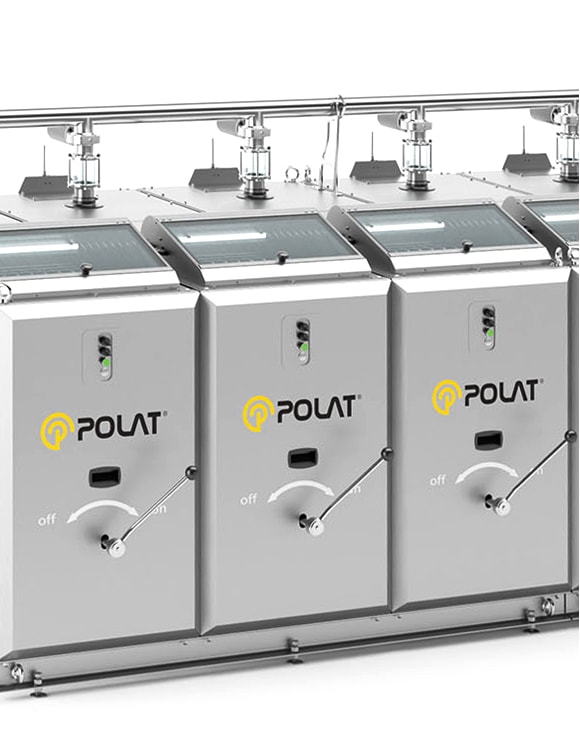

It is the equipment developed for olive paste to grow mature and leave the olive oil and which has high technology and can operate in different configurations and various capacities. It prepares the product for the next stage by kneading in a particular temperature and duration. It is manufactured from stainless steel in compliance with the food regulations and CE standards.

It is the molecular machinery which enables you to transfer your product between the processes. All surfaces which contact with the product are manufactured from stainless material. We offer you customized design and manufacturing options in different sizes and capacities.

Decanters are the devices with superior centrifuge technology. They are designed to separate the oil from the olive paste which is obtained as the result of the olive cleaning, breaking and malaxator stages. It enables the separation of your solid, liquid and valuable product with the centrifugal force by rotating in high speed in horizontal position. Our decanters are manufactured in compliance with CE standards and food regulations. We offer solutions for business facilities realizing manufacture in different capacities.

Sometimes, sediments are obtained together with the oil and water from the decanter. Oil vibrating equipment enables such sediments to be separated from the liquid. It is manufactured in compliance with the CE standards and food regulations.

Separators are the devices with superior centrifuge technology. They are developed for the separation of the water and contaminant elements present in the oil in less amount. They are placed vertically and rotate in a high speed. They separate the oil, water and solid particles thanks to its centrifugal force and enable you to obtain clean olive from the equipment. Our separators are manufactured in compliance with CE standards and food regulations. We offer solutions in different capacities for your business facility.

It is designed to separate the olive seeds in the olive pomace properly. Seed separator separates the seeds from the pomace paste and enables you to stock them separately.

It is designed to obtain clean and hot water required in the system. Exchanger systems use the water in the hot boiler. It is developed to boil the clean water to contact with the food and obtain water in the required amount.

We offer pump alternatives in different debits and capacities so that your products in liquid form can be carried from one point to another with zero touch in the most reasonable way.